- Bathroom Sets[3]

- Flush Valves[2]

- Toilet Tanks[10]

- Filling Valves[8]

- Other Accessories[10]

- Flappers & Tank Balls[5]

- Drains[3]

- Urinals[3]

- Screws[2]

- Plumbing Hoses[2]

- Toilet Push Buttons[4]

- Tank Levers[3]

- Toilet Seats[7]

- Moulds[7]

- Mould Design & Processing Services[1]

- Plumbing Traps[2]

- Toilets[2]

- Pipe Fittings[2]

- Towel Bars[1]

- Contact Person : Mr. Gong Peter

- Company Name : Xiamen Jielin Plumbing Co., Ltd.

- Tel : 0086-592-5796566

- Fax : 0086-592-5784557

- Address : Fujian,Xiamen,No.145,Xingqian Road,Xinglin,Jimei,Xiamen,Fujian,China

- Country/Region : China

- Zip : 361022

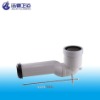

plastic injection mould for pipe fitting

♥Plastic injection moulding service♥

♥Products scale♥1) Electron product parts2) daily used plastic commodity3) car parts4) Medical equipments5) Sanitary ware parts6) OEM services are availableSpecifications

Plastic injection mould for pipe fitting .Good surface treatment .No deformation on products .Reasonable cost

Product Description

Mould Name: plastic injection mould for pipe fitting

Mould Design: CAD/CAM/CAE

Cavities: 1 cavityMould base: LKM, HASCO, DME etc

Mould Steel: H13 / 718H

Material HRC: 48-52

Runner: Cold runner / Hot runner

Ejection: Fully automatic ejection

Cooling: With properly cooling system

Treatment: Pretreat And Nitriding

Use Condition: -10 to 120 centigrade

Life time: 300,000-500,000 shots

Packaging: Wood case for mould Part Material: PVC,PP,PE

Color Standard: Pantone, RALTexture: VDI, YS, Mt

Step Processing Discription

1 Offer received & requirements confirmed

2 Quotation provided

3 Order placed

4 3D drawing designed

5 Mould manufacturing

- Steel preparing

- Wire-electrode Cutting

- NC, Engraving EDM

- Electrical Sparkle

- Polishing

- Mould Installation

6 Mould Testing

7 Samples confimed OK

8 Packing & Shipping

Our Advantages:

1. 3D drawing design for according to the 2D drawing or sample after order.

2. Photos of mould to customers weekly, providing a view of manufacturing process.

3. If parts order gets to a fixed amount, mould cost can be refunded.

4. When mould life is overdue, we will make mould free for second order.

1. 16 years' experience in mould designing and making

2. CAD/CAM/CAE system and advanced technology

3. CNC machining center, wire erose, EDM machine etc

4. strict quality management and reasonable price.

plastic injection mould for pipe fitting